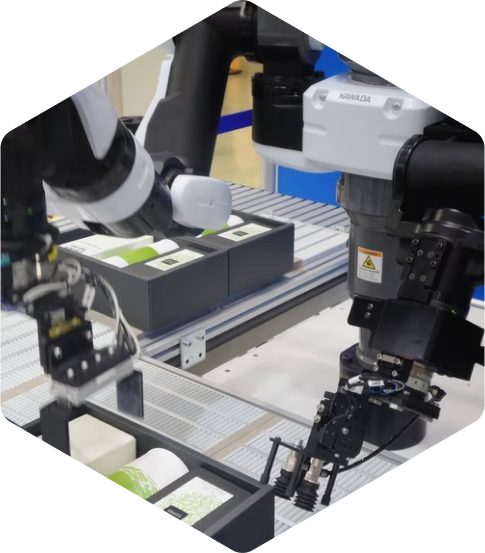

After the design phase and a purchase agreement has been made, OMNI gets to work producing the final product. But, before we start making plastic components, we have to create the mold to do so.

The majority of the products that OMNI manufactures require a mold of some description, and every mold is designed and manufactured in our facility utilizing the latest CNC milling technologies. Each material is unique and the material flow is different, different materials and durometers shrink at different rates, and the understanding and history of each ensures that your mold is cut to the exact specifications out of the gate.

Proper tooling design is essential to ensure the production of high-quality parts with minimal waste and maximum efficiency. As we delve into the specific application, we consider the mold design as it relates to compression molding, plastic injection molding or another molding manufacturing process we employ. We will review and ensure proper ejection or part removal, undercuts that may cause or create issues resulting in post machining operations, tolerances levels, mold surface finish, parting lines, draft angles, mold cavities, cross-sections, and gate location. All of these elements play a critical role in how your solution is manufactured. The part design and quality of the tooling is what drives our ability to create plastic parts repeatedly, holding consistent tolerances, to the correct quality level to meet every demand of the application.

There is a lot of buzz around plastic mold manufacturing for low volume production runs. At OMNI we can also utilize 3D printing technology to manufacture tooling, or molds, to produce a very small number of parts out of the production material to prove the concept. Plastic molds certainly have a place when prototyping to eliminate or minimize risk and future exposure. In addition to custom, low volume runs, OMNI also guarantees reasonable lead times so you can ensure your project will be completed on time.While many manufacturers sub out their mold making capabilities, we feel that controlling this process internally allows us to be extremely flexible and responsive to meet special requirements as they might arise. Keeping this work in house is a unique differentiator that also affords us the capabilities to manufacture ancillary components that are often required in a molded part.

#mold #molding #cncmilling #moldmaking #designandengineering