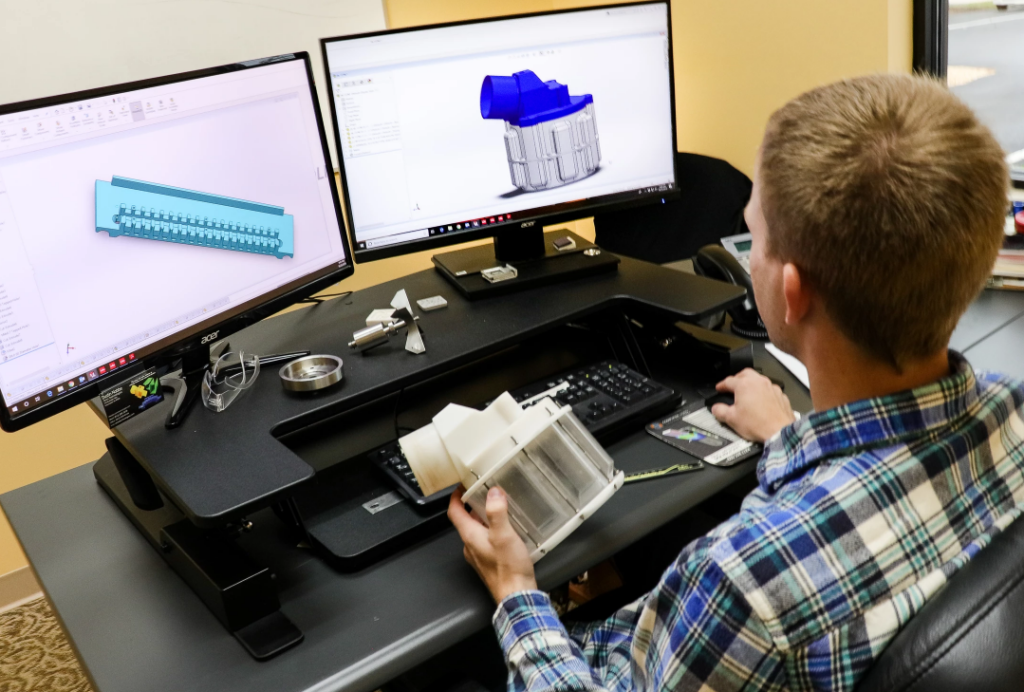

After evaluating the opportunity and verifying the best fit for both parties, we will start designing the solution. This is where we marry the design, material selection, manufacturing process, and decades of experienced team members committed to making your application successful. We will work with your design or create one from scratch to ensure that everything is properly considered. There is a lot that goes into the solution design process, specifically with dynamic plastic parts and components that are integral to your equipment. It is critical that the correct material is chosen for the application along with the right manufacturing process – whether it be spin-casting, injection molding, 3D printing, compression molding or one of our other plastic manufacturing methods – is selected based on several design considerations including part geometry, part size, optimal material selection (durometer or polymer) and order frequency. We then help to optimize the design and part functionality from a manufacturing perspective taking all physical requirements into consideration. Once we have settled on the manufacturing process, additional part design information and critical surfaces will be noted on manufacturing drawings. Depending on the manufacturing process, this may include sprue and gate locations, wall thickness requirements, additional draft angles, number of mold cavities, part surface finish, and ejector pin locations. Each molding process has similar basic principles, but are executed in very different ways.

With equipment requirements for sanitary designs being more and more critical, molding complete assemblies as a single homogenous item can present itself as a huge differentiator in the marketplace. Through a good product design and proper material selection, we can make sure that all of your sanitization, product contact and dynamic requirements are met.

Also included in this phase will be a discussion surrounding the additional benefits that additives and molded-in-place inserts can bring to the table – all specially designed and formulated for each specific application.

After the design has been discussed and agreed on, OMNI will work to present pricing for the products being manufactured. In order for us to provide the most accurate estimate it is imperative that all parties work cooperatively to make sure that the pricing matches the customers’ expectations. With so many variables at play, the more we know, the better complete, high-quality product we can provide. If there is a target price per unit that is trying to be achieved, we have options when designing and manufacturing the mold to add cavities as needed to try and achieve a target unit price. The same can be said if the goal is to keep the tooling cost down; design fluidity can allow us to simplify the mold and reduce the number of hours to create it. Ultimately, the goal is to develop a molded product that satisfies all of the requirements, quality, durability, price and lead time.

If you need an innovative design for a plastic component solution, OMNI can get started on your project today. Give us a call or fill out our contact form and one of our representatives will be in touch!

#design #engineering #mold #moldconstruction #sanitization #molding #durometer #prepolymer #manufacturing