When manufacturing custom polyurethane and plastic parts, precision is not a choice — it is imperative to creating quality components. At OMNI Technologies, we understand the importance quality control and precision have on creating top-of-the-line components for OEMs and organizations utilizing plastic components.

What is Quality Control?

Quality control (QC) is one of the most critical steps in the manufacturing process, where custom-made components are inspected to ensure the quality of the overall product. If products are not high quality, have defects, or were improperly created, they can harm our customers and their workplaces. Therefore, product quality is emphasized in this process, ensuring that the molded parts we produce are up to our standards and beneficial for our customers.

OMNI’s Manufacturing Process

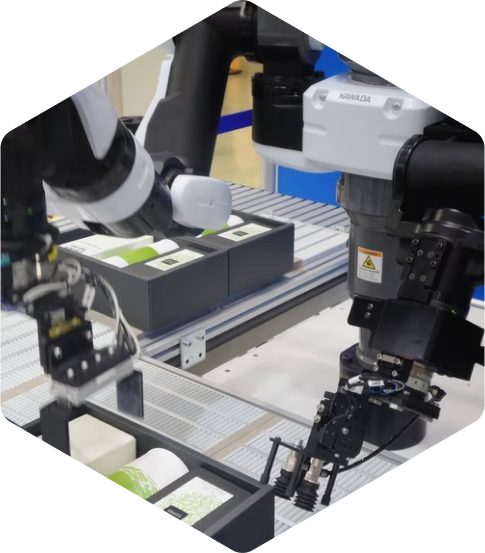

At the heart of OMNI Technologies’ strengths lies a manufacturing process that is both an art and a science, where precision is not negotiable—it’s inherent. Our commitment to delivering custom plastic and polyurethane parts is exemplified through various methods, with our most popular being compression molding.

The Plastic Product Design Process

To manufacture high-quality plastic products, our customers first meet with our design team to discuss the purpose their components will have. With a deep understanding of the customer’s needs for the molded parts, our design team will then propose a plastic material, required durometer, and molding process best for the intended use. While we might propose multiple options, our team will share the best possible options available to create high-quality components.

Once that is approved, our team will begin to collaborate regarding mold design and prepare for the plastics manufacturing process. During the mold design process, our team will look for areas with potential for concern, such as thin walls that might experience deformation, anticipated shrinkage, or areas that require high precision. From there, we will create the mold cavity and review it for a quality inspection to ensure all products created meet our standards.

QC and Production Runs

Once the mold is complete, our team will then begin production processes to create the custom components. A member of our team will monitor production with visual and physical inspections in real time to ensure that quality standards are met. From monitoring the temperature of melted polymers to ensuring molds are completely filled to reduce the occurrences of voids, our team is dedicated to ensuring all quality standards are met.

Throughout the production process, our team’s quality management processes put the client’s needs and the quality of the plastic products first.

Customization of Plastic Components

While compression molding is one of our most common methods of production, we do create plastic products using a variety of methods. Whether our team is utilizing plastic injection molding for intricate details or other specialized products tailored to unique final product requirements, our design team adapts our process to suit the distinct needs of each process.

Quality Control at OMNI

Quality control isn’t a phase in our process; it’s woven into the very fabric of manufacturing. At every step, from material selection to the final molding, stringent quality checks are implemented to guarantee that each part leaving our facility meets the uncompromising standards set by OMNI Technologies.

This includes evaluation of the product during the design phase, testing and assurance of molds and thermoplastics used, and a final review of products before we share them with our clients.

What Happens When We Find Defective Parts?

We immediately pull the part for further review if we find that the finished products are defective. Our team will then investigate each step of the process, from the mold itself to the polymers used to even the process parameters involved. From there, our team will work toward fixing the system to continually produce plastic parts of the highest quality.

Choose OMNI For Your High-Quality Plastic Components

At OMNI Technologies, the manufacturing process is not merely a means to an end; it’s a commitment to crafting excellence, one molded part at a time. Our design team and engineers are passionate about creating custom plastic components that meet quality control measures.

Are you ready to craft your custom components? Contact us to meet with our Product Development team.