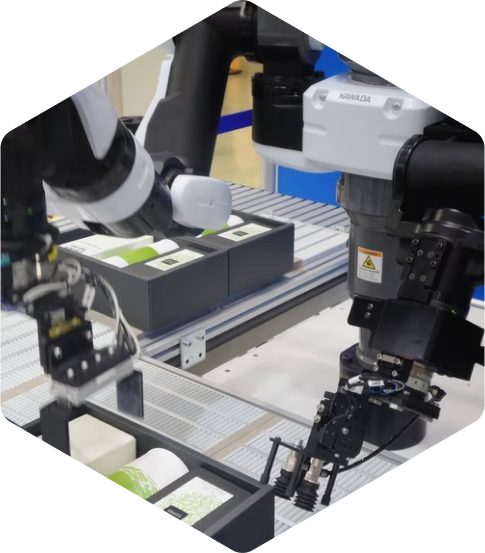

Creating your custom plastic parts can be the beginning of a new era for your organization. With custom parts specifically created for OEMs, your organization can rest assured of our commitment to the highest quality standards. This allows you to focus on your operations, while we respond to your needs. However, the success of your plastic components largely lies within the careful selection of the right plastic material.

At OMNI Technologies, our team understands that plastic material choice is a crucial step in the plastic design process, as it can significantly impact the performance, durability, and overall success of your molded components.

Understand the Demands Of Your Plastic Products

Before selecting the plastic material and beginning plastic product design, we first need to have a clear understanding of the application, and of your product. This often includes considering specific requirements your plastic parts need, as well as any challenges your component will face in application. You might also consider factors such as product color preferences, temperature resistance, potential chemical exposure, and mechanical stress from repetitive use.

During our collaborative opportunity evaluation, our team will undergo a deep dive with you to strive to understand your wants as well as your needs. With your component’s focus in mind, our designers and engineers will tailor our recommendations to your unique application. We do not send your products out to an external design company and instead will draft and create your products in-house at our facility, ensuring the protection of your product’s design.

Consider If Your Products Need to Be Food-Safe

When selecting your material, you might also have special concerns about the product’s use, especially if the components come into contact with food products. For plastic components that are used on food production lines, you might need color-coded products that indicate certain allergens are on the line as well as food-safe materials. Our products can be formed in a variety of colors, but if you do not see the color best for your application, our design team can work with you to formulate the color best for your needs.

Selecting the Right Production Method

Another key component of selecting the right plastic material is to consider not only the plastic part design but also the method of production. Depending on the part itself, you might consider prototyping with different molding methods during the product development process, however, our design team can help you select the right molding method and tool design for your plastic products.

When considering the production method best for your custom component, we will take into consideration for the mold design things such as:

- Overall part function

- Geometry of the parts

- Are there any mechanical locks or undercuts needed?

- Will knit lines create issues?

Your component’s requirements will impact the best method for your use, especially if you have designs with thin walls, which might cause sink marks during production.

At OMNI, our facility has the capability to produce custom plastic components through a variety of methods, with our most popular being compression molding. We also offer:

- Open casting

- Spin casting

- Large casting

- Injection molding

- 3D printing

Types of Plastic Materials Offered at OMNI

Plastic materials come in a variety of types, each with its own set of properties and advantages. At OMNI, we specialize in thermoset polymers, with our largest focus on high-performance silicones and urethanes.

We offer the following plastic and urethane materials:

- Urethane

- Hi-temp urethane

- Silicone

- Hi-temp silicone

- Nylon

- Acetal

- Delrin

- UHMW

- Teflon

- ABS

- ASA

- TPU

- Resin

- Bulk compound materials

- Urethane foams

- Polycarbonate

- PEEK

- Polypropylene

- Polyethylene

Each form of plastic has its own specific applications and methods for how it can be molded.

Choose OMNI

Choosing the right plastic material for your molded parts is a pivotal step in ensuring the success and longevity of your custom components. Choosing the right partner is another. At OMNI Technologies, we recognize the significance of this decision and are committed to guiding you through the process with expertise and precision. By combining expertise in part design, production methods, and a diverse range of plastic materials, OMNI Technologies empowers your organization to embark on a successful journey of creating custom plastic parts that not only meet but exceed expectations.

Are you ready to begin creating your custom plastic OEM components? Reach out to our design team or call us to get started with the OMNI Process today.