In the realm of modern manufacturing, plastic has become an indispensable material. Its versatility, cost-effectiveness, and ease of processing have revolutionized industries, including the manufacturing industry.

Cost Reduction Through Polymer Usage

Leveraging plastic components can be a strategic game-changer for OEMs and manufacturers as they seek to drive down production costs. This cost-saving potential is most pronounced when dealing with high-volume production runs, where scale comes into play.

Plastic’s cost-effectiveness begins with the manufacturing process itself. Plastic molding processes minimize labor requirements, instead relying on molds themselves. Once the molds are created, they can be used repeatedly without significant degradation, reducing tooling costs per unit. As a result, the upfront investment decreases over the course of a high-volume production run.

Plastic materials are often more affordable than alternative materials, like stainless steel. The use of plastics and polymers is particularly advantageous for organizations that aim to produce lightweight yet sturdy components. The lower material costs can have a cascading effect on the overall production budget, permitting manufacturers to allocate resources to other critical areas.

Product Quality of OMNI’s Plastic Parts

The choice of materials used in manufacturing and OEMs greatly impacts the quality of the end product. This is where molded plastic components shine as a beacon of reliability and consistency, enabling manufacturers to uphold their commitment to delivering high-quality products to customers. Plastic materials possess the coveted characteristic of durability and resilience against weathering and corrosion, all the while offering much versatility.

Plastic components are able to be manufactured with remarkable repeatability and tight tolerances. OEMs, driven by stringent quality standards, harness this process to ensure that every plastic component produced conforms to exact specifications.

The net result is that manufacturers can have the utmost confidence in the quality of the products they deliver to their customers. The ability to maintain these high standards not only instills customer trust but also mitigates the risks associated with product recalls, warranty claims, and reputation damage.

Reduced Time To Market

In the fast-paced and fiercely competitive landscape of today’s manufacturing industries, the adage “time is money” has never rung truer. Plastic components, brought to life through the efficient process of plastic molding, are excellent results of rapid production. Once the molds are meticulously crafted, the production cycle time becomes impressively short. This speedy turnaround time has proven to be a game-changer in industries where time is of the essence.

The ability to swiftly produce plastic components aligns perfectly with the demands of today’s consumer-driven markets. Customers are not only seeking high-quality products but also expecting these products to hit the shelves or digital marketplaces promptly. This expectation is shared across a spectrum of industries, from plastic packaging to innovative medical devices that can save lives.

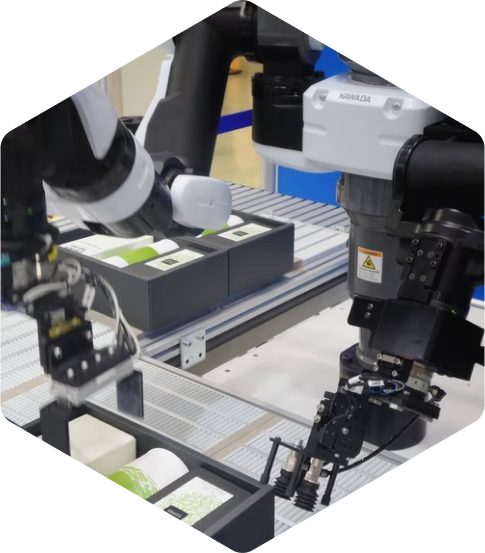

Increased Efficiency in Manufacturing

Efficiency has always been a cornerstone of successful manufacturing operations, with the ability to produce components quickly and in large quantities being more critical than ever. Molded plastic components, with their capacity for high-volume, high-speed production, have emerged as a linchpin in the quest to optimize manufacturing efficiency for both OEMs and their manufacturing partners.

Plastic components enable manufacturers to quickly adapt to changing market conditions, fluctuating demand, or shifts in product specifications. This flexibility positions manufacturers to capitalize on emerging opportunities or navigate through unforeseen challenges effectively.

Additionally, efficiency extends beyond the factory floor. Plastic components are inherently lightweight, reducing transportation costs and environmental impact. Their durability also contributes to more extended product life cycles, reducing maintenance requirements and waste. In this way, molded plastic components align with sustainable practices, further enhancing the efficiency of the entire supply chain.

Reduced Scrap Rates Through Plastic Molding

Minimizing waste not only reduces the overall plastic used in the production process but also lowers costs and environmental waste. With this overall reduction in product use, plastic components emerge as a strategic asset for manufacturing partners, offering a distinct advantage in the form of remarkably low scrap rates. This attribute not only helps reduce costs but also stands as a testament to the potential for improved profitability.

The inherently low scrap rates associated with plastic component production are a direct result of the precision and consistency offered by molding technologies, such as compression and plastic injection molding. Once the molds are perfected, the production process unfolds with minimal variability. Each production cycle yields components with tight tolerances and uniform quality, leaving very little room for defects or discrepancies. This level of predictability in the manufacturing process is the antithesis of waste, as it significantly diminishes the likelihood of producing parts that don’t meet the required specifications.

Low scrap rates also translate into more efficient use of resources. In industries where every component must meet stringent quality standards, the reduced need to rework or scrap defective parts results in substantial savings and directly contributes to increased profitability.

Moreover, lower scrap rates are a testament to the reliability of the manufacturing process itself. The consistency achieved through plastic molding ensures that the vast majority of components are produced correctly the first time.

Choose OMNI As Your Manufacturing Partner

In the ever-evolving manufacturing landscape, choosing the right partner can make all the difference between mediocrity and excellence. At OMNI, we stand as your unwavering ally in the quest for manufacturing superiority. Our commitment to delivering high-quality, precision-engineered solutions is matched only by our dedication to innovation, efficiency, and sustainability.

Our OMNI design process can help you determine which molding technique, is best suited for your unique project and requirements.. In addition, we can review our library of materials and help you choose which material is best for your custom manufacturing needs, such as thermoplastics, polyurethane, polyethylene, polycarbonate, or other plastic materials. Together, we can redefine what’s possible, setting new standards of excellence and propelling your plastic products to the forefront of your industry.

Get started on designing your custom manufacturing component — share your ideas with us today.