Editor’s note: This post was originally published on OMNI in 2019 and has been updated to reflect the latest information.

What is End-of-Line Packaging?

End-of-line packaging, also sometimes referred to as tertiary packaging, is exactly that. This equipment takes the finished shelf-ready product, places it into a case or carton, conveys that product to be palletized, receives stretch wrapping, and is then prepared for shipping. This is the last step before the product leaves the manufacturer’s dock and is sent to a grocery store, retail location, or another warehouse for e-commerce distribution.

Primary Purpose of End-of-Line Packaging Equipment

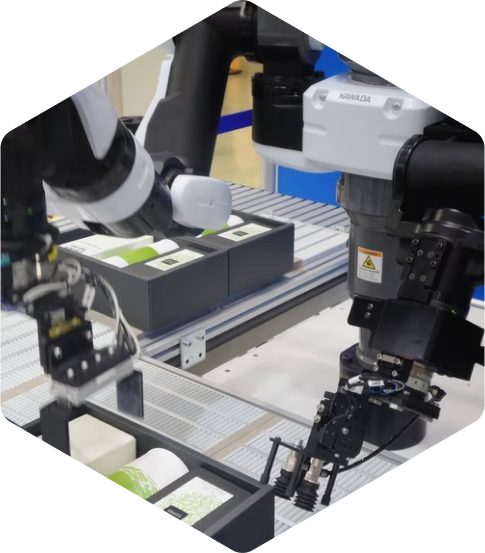

The sole purpose of end-of-line packaging solutions is to protect the finished product during the transportation process. Although various types of packaging machines and robots can be found throughout the entire packaging process, many OEMs are using robotics to maximize flexibility and automation in their end-of-line equipment. End-of-line packaging tends to be the most consistent, while there is a lot of overlap in Primary and Secondary Packaging.

To learn more about Robotics in End-of-Line Packaging, check out our recent blog here.

End-of-Line Packaging & Custom Molded Plastic Parts

As new equipment is being developed, physical space constraints and flexibility are significant drivers for the end-of-line packaging solutions available on the market. OMNI’s commitment to making the most of your next design and ultimately your customer’s success is top of mind. Whether that be through robotics, case erecting, palletizing, or wrapping, OMNI will strategically work with you to match your needs and expectations when implementing plastic products into your equipment – all with the goal of optimizing your packaging operation.

Plastic Parts For End-of-Line Packaging Systems

Many leaders of the packaging industry trust plastic and polyurethane parts for their high-speed, high-quality packing machines. Package types and display packaging vary, so it’s important the equipment is versatile and can handle multiple platforms.

Some of the end-of-line packaging equipment types OMNI has engineered parts for:

- Tray Packing

- Case Packers

- Case Sealers

- Case Erectors

- Shrink and Stretch Wrappers

- Palletizing Automation / Robotic Palletizer

- Bundling

- Labeling

OMNI Engineers Molded Polyurethane Components for Primary Packaging OEMs

OMNI wants to assure that you know you are in good hands no matter what packaging machinery you employ. OMNI has been serving the production line industry for over 44 years and understands the pressures that come with it; from supply chain issues and labor costs, to design limitations and manufacturing feasibility.

Our innovative team at OMNI can customize and deliver a tailored solution to you, no matter your project. We have the ability to mold complex geometries with consistency from part to part, to ensure that each part is not only dimensionally correct but performs how you need it to.

OMNI has the design knowledge to produce the highest quality product with superior functionality and performance. We are ready to collaborate with you to identify the best solution—from design and material selection to execution and delivery.

If you’re looking to reduce downtime and increase throughput in your packaging machines, contact us today!

#endofline #endoflinepackaging #packaging #wrapping #robotics #caseerecting #palletizing #omni #packagingsolutions #shippingpackages #stretchwrap