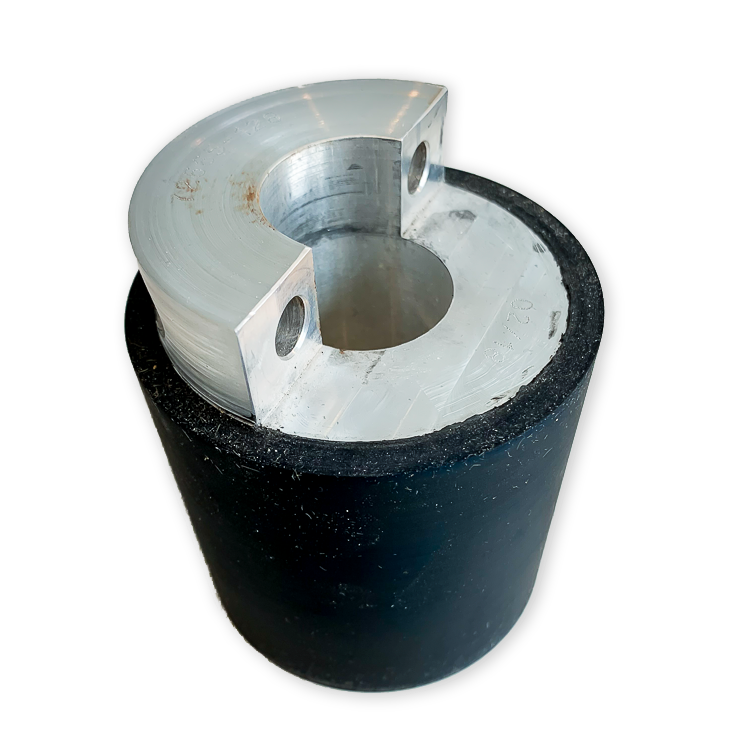

Coefficient of Friction by definition is a measure of the amount of friction existing between two surfaces. A low value of coefficient of friction indicates that the force required for sliding to occur is less than the force required when the coefficient of friction is high. For context think of ice on steel, this would have a very low coefficient of friction, while rubber on pavement would have a very high coefficient of friction.

While this may seem like an abstract subject, it has everyday real world implications in the packaging industry. Packaged products must slide through buckets on cartoners. Food products, sometimes very tacky due to oils or sugars, must move through conveyors, funnels, scales, and feeders. Baggers and Stand up Pouching equipment use coated rollers to advance and stop film during indexing at incredibly precise increments to keep the registration of packaging graphics in tolerance. All of these examples show how critical managing and designing the Coefficient of Friction of the components of your project is.

At OMNI we have extensive experience in engineering just the right material choice for your critical application. When working with our high performance Polyurethanes and Silicones we can help you find a solution through durometer change which means the hardness of the material. We also offer solutions through implementation of additives to the material from our vast list of choices. Our goal is to work with you and find a material formulation that will give you the slip or grip that you need. At OMNI we are dedicated to partnering with you to find the right design, the right material, and the right additives at the right price to fit your application.