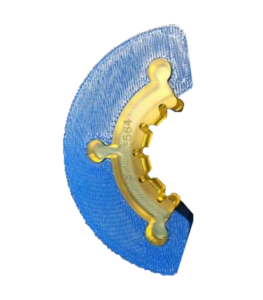

Here is a project OMNI worked on with a customer whose equipment fills bottles. At a point in the filling process the bottles are transported by a Star Wheel, at the time the Star Wheel used a rubber pad that was bonded to the inside radius to improve grip while clutching the bottles. They experienced problems with the rubber pads as they would breakdown quickly, leaving the original pads operating with a loose grip causing disruptions leading to frequent and costly downtime for changeovers.

With OMNI’s expertise, it was decided OMNI could remove the rubber to recover the existing Star Wheel, machine details that would allow the Star Wheel to accept a removable Gripper Pad.

The custom formulated and redesigned Gripper could be removed and installed with no tools in mere seconds all while providing an extended part life between replacements. The manufacturer’s problems solved on several fronts with pads that last significantly longer and only requiring seconds to change over increased production, decreased labor, and freed up valuable resources.