Why Omni?

Why do industry leaders trust Omni?

For over 45 years, Omni Technologies has been a trusted partner for custom plastic, silicone, and urethane components. We’re passionate about both plastics AND people, offering bespoke solutions from prototyping to full production. As industry leaders, we blend our passion for plastics with a commitment to our clients, providing personalized solutions for complex problems. At our core, we want to empower companies to overcome challenges and achieve their fullest potential through the use of engineered high value plastics.

What makes Omni different?

At Omni Technologies, our core philosophy revolves around putting people first and plastics second. We believe in delivering legendary customer service by upholding the highest standards of integrity and honesty. While we aim for perfection, we are human, and will always do our best to make things right in any situation. Our success comes from a passion to serve our customers and solve complex issues through the use of engineered molded plastics.

What problems does Omni solve?

Omni is hyper-focused on solving complex issues through the use of engineered plastics. Companies often partner with Omni when they are looking for an expert in plastic molding and manufacturing. Every project is different, so every project is evaluated with a fresh lens to gain perspective on goals before suggesting potential solutions. Omni is often approached when companies are looking for components that are too complex for 3d printing, but do not require the volume necessary to justify the expensive setup and tooling costs associated with injection molding. Companies trust Omni’s expert knowledge of polyurethane solutions to improve efficiency and reduce costs, and to make sure the right manufacturing process aligns with their goals.

How can Omni help us?

FOOD SAFE PLASTICS & URETHANES

Omni is deeply committed to protecting people and their safety by creating plastics and urethanes that meet FDA and EU food-safe standards. Understanding the importance of these regulations, Omni carefully designs components that help ensure the health and well-being of consumers. By partnering closely with clients to understand their business, equipment, and unique needs, Omni delivers thoughtful, reliable solutions that prioritize safety while adding value to their partners.

METAL & XRAY DETECTABLE MOLDED COMPONENTS

As experts in metal and Xray detectable custom molded polyurethane components, we understand how important it is to prevent contamination from worn or broken equipment parts. Omni can tailor these detection agents to seamlessly integrate with existing detection systems, whether metal or X-ray based. These solutions are designed with flexibility in mind, enabling future customization as your detection needs evolve. By prioritizing safety and adaptability, Omni Technologies helps safeguard the integrity of food production and packaging operations.

INNOVATION WELCOME

Have an idea but unsure how to bring it to life on a larger scale? Omni understands that every manufacturing process is unique, and a one-size-fits-all approach doesn’t work for every business. With over 45 years of experience, our team is here to help evaluate all possible options and guide you toward the best solution for your specific business model. Whether you need prototyping, small production runs, or full-scale manufacturing, Omni is your trusted partner for plastic, urethane, silicone, and polyurethane components. Let us help turn your vision into reality with solutions tailored to your needs.

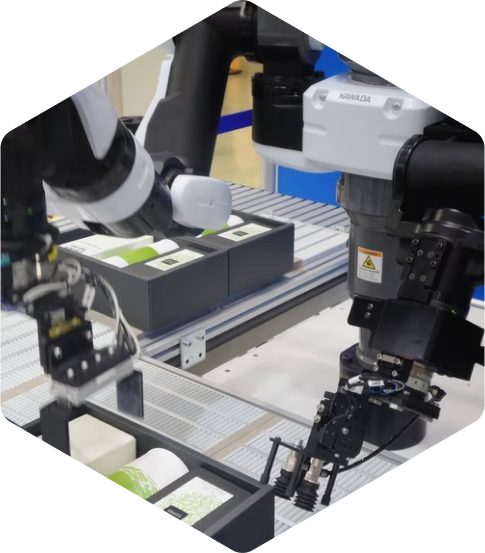

COMPLEX DESIGN READY

Omni specializes in thermoset polymers, but more specifically high performance silicones and urethanes. Over the years Omni has developed many molding methods to produce our customers end product. These molding operations range from open cast, compression molding, spin-casting, injection molding, transfer molding, and large volume machine casting. Our favorite project is a new project, and we love hearing “we haven’t been able to find anyone else to do this for us.”

PROUDLY MADE IN INDIANA

Omni is centrally located in the heart of Greendale Indiana, just outside of Cincinnati Ohio. Our 55,000 sq. ft. facility houses all aspects of the manufacturing process from engineering, to mold making, to full production cycles. We’re grounded by our midwestern values, and dedicated to serving our customers with honesty and integrity.

RAPID CHANGEOVER READY

Omni has assisted many customers with innovating custom solutions to dramatically reduce their changeover times on high use equipment. Color coordinated components can now create a quick and easy visual indicator to assure the changeover has been completed. Our primary focus is to improve efficiency, save time, and reduce your costs.