Recently Omni was asked to help develop a polycarbonate (PC) Wind Break or Enclosure for one of our long term OEM partners. This partner is the market leader in providing front to back solutions for processing, weighing, and packaging foods, pharma, and consumer goods. Their equipment can offload the raw product from trucks all the way through processing, seasoning, weighing and then bagging or bottling and then case packing. For this application our partner faced a challenge they had not encountered on any prior projects. The product is pharma related and is being conveyed and then weighed in Multi-Head Weighers and then dosed into bags and bottles. The product is extremely expensive and also extremely fine textured. Even in clean room environments the fine product was migrating from activity as simple as closing a door to the clean room. Weights from the scale were being affected. For these type applications these Weighers can be accurate to .1 gram at speeds of up to 200 doses per minute. The problem was not with the equipment but with the environment. The solution was to design and manufacture a Windscreen or Enclosure that would effectively surround the Weigher and eliminate any air movement that could agitate or move the product and affect package weights.

Our partner thought of Omni first as we are their key vendor for plastic parts and components. Their Engineers designed an assembly that would interface with the equipment seamlessly and not impact in any way the functionality or, if required, the accessibility of the Weigher. Omni was asked to collaborate with the design as our partner is expert in metal fabrication but not engineered plastics. The Omni team helped with improving the design to preserve the functionality of the assembly while making the design more conducive to manufacturing.

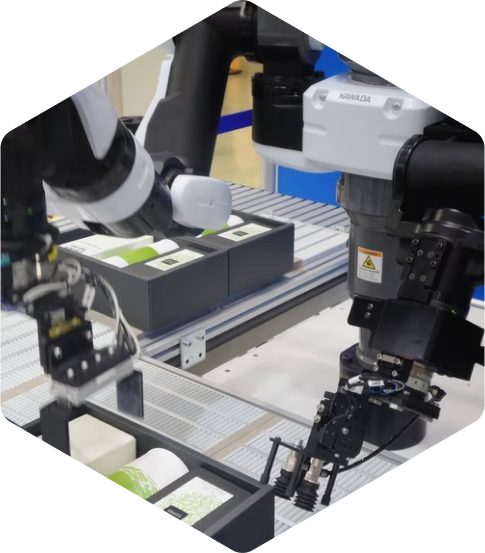

The next step was to produce a fabricated version of the Enclosure that had chemically welded seams (See photos). The process was comprised of cutting all panels from stock FDA approved PC and then chemically welding the pieces to create the assembly. This first generation assembly was very well received at the plant level. Our partner however, wanted a cleaner design with few or no welds that would be more easily sanitized and also more durable with no seams to fail.

The second generation of the Enclosure was then designed for a vacuum formed process (see photos). In the vacuum forming process polycarbonate sheets are heated and stretched to help with consistent cross section thickness and eliminate air bubbles that can be created when forming. The sheets are then formed over a male form or mold and drawn to the mold with vacuum. The parts are formed oversized with excess material and then trimmed to size with a CNC trimming router. The final result is a formed part that has no seams that can fail or harbor bacteria and a much more transparent guard that has no seams to obstruct view of the equipment. While there was some investment in tooling for the second generation cover upfront the assembly costs are much lower due to less material waste and far less labor vs. the fabricated version.