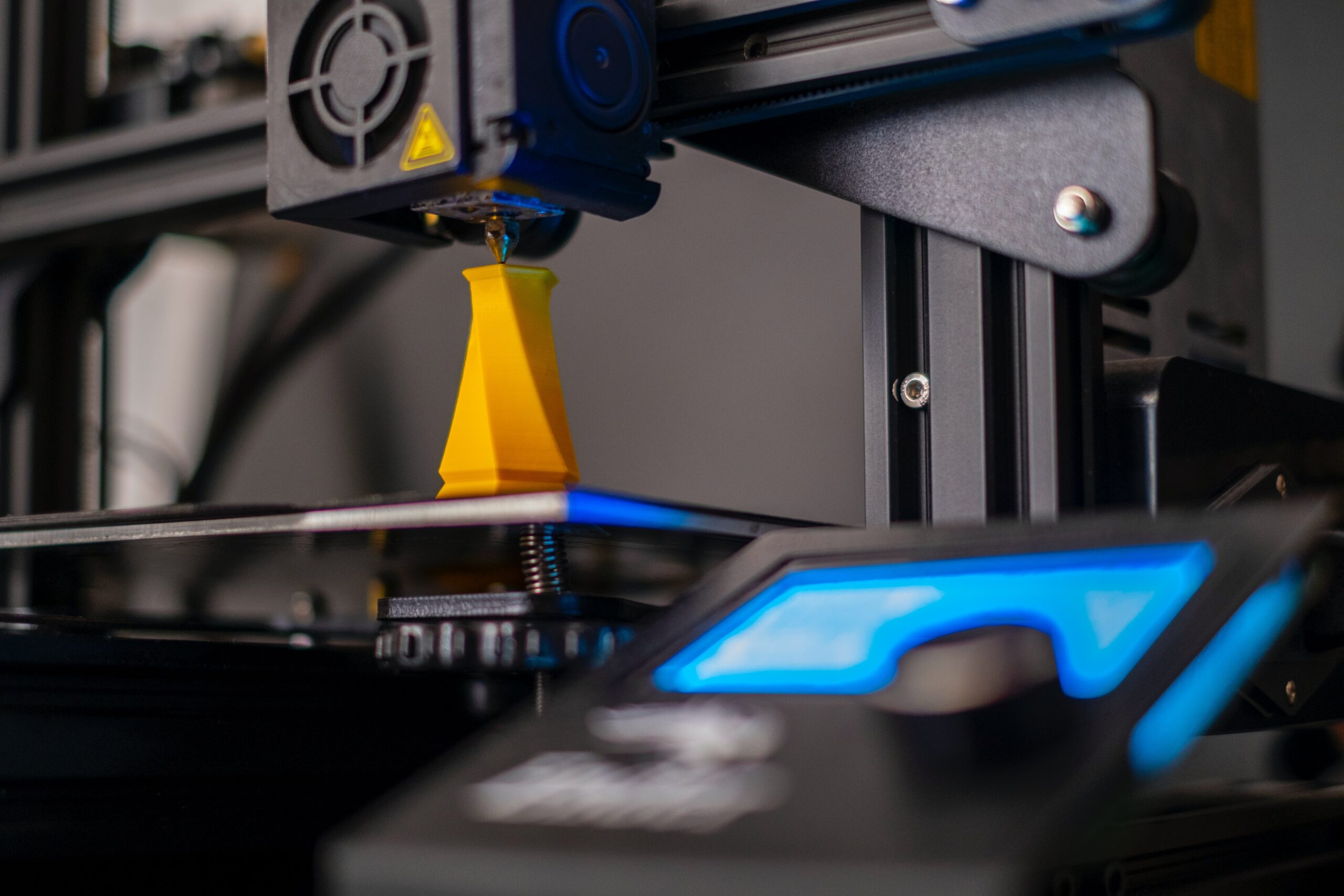

For most OEMs, achieving affordable and durable part manufacturing remains virtually unfeasible. As the precision and complexity of end-use components for intricate machinery expand, manufacturers know they must keep pace with new technology. They need to consider faster and more accurate prototyping methodologies to speed up the design-to-manufacturing pipeline. Thermoplastic polyurethane (TPU) filament and 3D printing are becoming the go-to prototyping tools for OEMs to create quickly manufactured and swiftly iterated prototypes. With precise measurements, a well-crafted blueprint, and spools of thermoplastic filament, OEMs can create finalized designs faster than ever. With modern 3D printing prototyping, such end-use components can be created quickly and expertly. The technology is there and is within reach.

A History of 3D Printing Using Thermoplastic Polyurethane

Before the widespread availability of plastic filaments and at-home printing, the predecessor to the current 3D printer began in the early 1980s in Japan. Hideo Kodama invented an intricately layered UV-activated resin that hardened polymers. Unfortunately, his technique was much too costly and challenging to produce quality results consistently.

Soon after, as the early 2000s started, 3D printing technologies looked toward using other materials, such as liquids and powders, as alternative filaments. Though the new materials worked well in many instances, they were expensive. Making bulk manufacturing and at-home production nearly impossible.

Eventually, between 2009 and 2010, researchers introduced TPU and polylactic acid (PLA), which later became commercially available. This adoption of plastic-based filaments led to many of the latest innovations within 3D printing and much of the conversation surrounding TPU filament in parts manufacturing.

How Does TPU Filament Help Manufacturing?

Advancements in 3D printing technology have become more refined over the years within the manufacturing space, especially with 3D printing materials readily available. Industries have begun leaning heavily on its use as a prototyping tool.

Some manufacturers have identified TPU as a potential material in manufacturing end-use components. It is worth mentioning that TPU has end-use component applications in other manufacturing spaces due to its rubber-like qualities and abrasion and chemical resistance. However, some industries, such as food packaging and processing, cannot benefit from its end-use component. With food packaging and processing specifically, thermoplastic filament prints its layers wide, which could introduce bacteria. The risk is too high for 3D-printed products to come into contact with packaging and processing food.

TPU filament remains an incredible tool in risk mitigation as it allows for affordable, high-quality prototypes that let designers see firsthand the positives and negatives of a given design. Its natural qualities, such as heat resistance, elasticity, and more, enable early testing cycles to run, comparing it to the soon-to-be-molded polyurethane component. Achieving durable part manufacturing is now economically possible with TPU.

Find a Molded Component with OMNI Technologies

We at OMNI Technologies excel at creating continual progress in designing and prototyping your custom polyurethane component. A robust and sustainable design starts with the proper material and a clear goal. OMNI begins the manufacturing process with a thoughtful design, a clear component goal, and a solid idea of the component’s required properties and function.

OMNI is a leading designer and manufacturer of dynamic polyurethane components. We provide our partners with their equipment’s most durable, molded polyurethane components. Let’s work together to help you get the best value for your OEM parts. Get in touch with OMNI today to get started!