Why choose plastic? More specifically, why choose polyurethane? It’s a great option to replace steel in many OEM applications for a variety of reasons—from price to durability. But despite the wide range of benefits of using custom plastic molded parts in manufacturing, there are several common misconceptions of polymers and polyurethane—most of which are related to the plastic’s quality and versatility.

Let’s dig into some of the misinformation and bust these common myths of polyurethane.

Myth #1: All Plastic is the Same

In fact, there is a wide range of plastics available for many different applications.

Polyurethanes are a family of plastics and include a broad spectrum of products, from polyurethane foam in mattresses to polyurethane coating, and components for OEMs like what we produce at OMNI technologies.

There are several types of plastics, but polyurethane is a thermoset. These are either cast molded or reaction injection molded (RIM). Thermosets offer better performance in high temperatures and are less likely to bend or break.

Polyurethane is created through a chemical reaction between diisocyanates and polyols. This complex chemical structure allows our engineers to tailor the chemistry of the urethane to meet your specific design requirements—from color and hardness to metal detectability and more.

Myth #2: Plastic and Polyurethane are Inferior to Metal

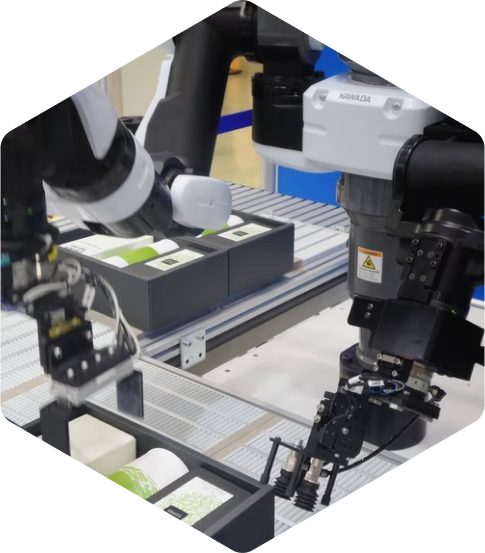

Stainless steel is often a first choice for OEM applications due to its durability. But did you know that polyurethane is impact and abrasion-resistant? With a wide range of hardnesses, any durable plant part is possible with engineered polymers.

OMNI has the ability to create parts that are x-ray and metal detectable. These parts are critical for efficiency and safety in the food, beverage, and toy industry applications. We stand by our durable and reliable products, but we know accidents can happen for a variety of reasons. Having a metal detectable part gives you the ability to detect and find any broken pieces within the processed or packaged product in case of an accident to prevent contamination.

Polyurethane has a relatively short lead-time, especially compared to the current state of steel with the current supply chain disruptions. At OMNI, we house all of our processes under one roof – so we feel less of an impact from supply chain issues, giving us the ability to deliver at a lower cost and quicker timeline.

Engineered polymers are less expensive and in some cases less than half the cost of other options. Not only are you saving money from the product itself, but also have the opportunity to decrease your operating costs through improved efficiency, part lifespan, and downtime.

Myth #3: Plastic Limits Shape and Size

Engineered plastics actually increase flexibility and customization options. This complex chemical structure allows our engineers to tailor the chemistry to meet specific design requirements.

Some parts may need to be sturdy and impact-resistant, while others may require the ability to be bendable and pliable. At OMNI Technologies, we manufacture polymers from a 20 SHORE A to an 85 SHORE D.

We have the ability to add various pigments during the manufacturing process to create a variety of custom looks. With over 20 different color selections, we can match your organization’s colors or rotate ‘wear parts’ based on batch or season.

OMNI Engineers Polyurethane Solutions Through Optimized Product Performance

No matter your project, our innovative team at OMNI can help customize and deliver a tailored solution. We have the design knowledge to produce the highest quality product with superior functionality and performance. We are ready to collaborate with you to identify the best solution—from design and material selection to execution and delivery.