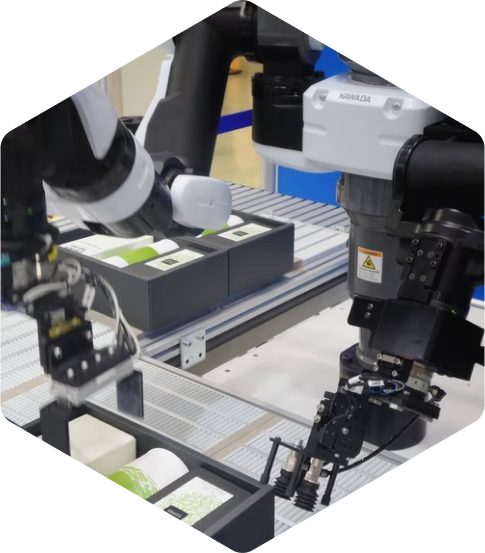

When designing components on your packaging equipment, what limitations do you work within? Stainless steel is often a go to component material in the packaging, processing, and industrial automation industries. Yet, other options exist that remove common stainless steel limitations like machining costs, complex geometries, abrasion and impact resistance. Try polyurethane instead, removing your design limitations and giving you a whole new approach to your overall packaging systems, and individual components.

Polyurethane, a versatile plastic material, with extreme flexibility and durability benefits is our material of choice. We custom engineer polyurethane to the specific application and environment.

Below is a list of advantages when your equipment uses parts made of polyurethane:

· Color Ranges

Various pigments can be added to polyurethane in the manufacturing process can create custom colors for safety, coordinating change parts, or branding initiatives.

· Short Production Lead Times

Paralleled to conventional thermoplastic materials polyurethane can have a relatively short lead-time.

· Extensive Range of Hardness Polyurethane can be manufactured from 20 SHORE A to 85 SHORE D

· Abrasion & Impact Resistance

· Tear Resistance

· Resistance to Water, Oil & Grease

· Electrical Properties

· Wide Resiliency Range

· Strong Bonding Properties

· Performance in Harsh Environments · Economical Manufacturing Processes